Who wants to live forever? ….er, offshore wind projects, apparently.

May 2018

Offshore wind has basked in the media spotlight this past 12-18 months, with announcements of record low pricing for upcoming projects. The drivers behind this are many (we previously explored these – cost reduction blog), but one secret weapon which has contributed to this has remained in shadows – Life Extension.

It’s easy to do – add another 5 columns into your financial model and you can improve project return anywhere from 0.5% to 1%. And we’re not just seeing it done for proposed new-builds; more and more, operational projects are coming to market with extended lifetimes. 30 is the new 25!

Obviously, my blasé intro hides the ultimate complexity of life-extending a project and I want to use this series of blogs to explore the issue in greater detail. In essence, what do you as an investor need to think about before buying into a project?

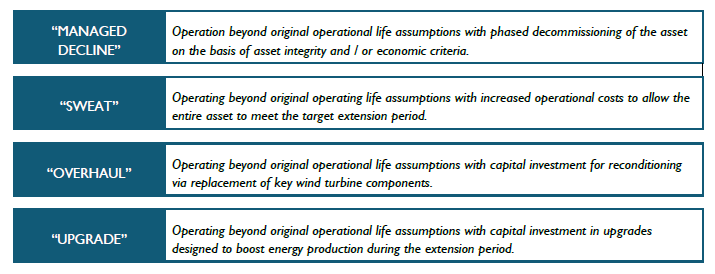

Before we embark on this journey, let’s quickly define what we mean by ‘Life Extension’. In Everoze parlance this involves the continued operation of an asset without swapping-out any of the major infrastructure. It should be view differently from Re-powering (where key infrastructure such as the WTGs may be replaced). The following options are available:

The first Blog of the series will focus on foundations, given their critical role in wind farm life expectancy. They are, unlike WTGs & cables, generally harder to inspect, especially around the life-limiting features.

So, without further adieu, let’s begin!

Blog 1: Focus on Foundations

Notwithstanding wind turbines, foundations are a key driver of what can be achieved for life extension. The issues are concept specific, but for this blog I’ll focus on the most widely adopted foundation choice – monopiles.

At a high-level, the key drivers for monopile foundation life can be characterised as follows:

- Design assumptions

- Ground conditions

- Operational asset integrity

In practice, the above drivers are intrinsically linked, with a foundation’s life pre-determined at the design stage.

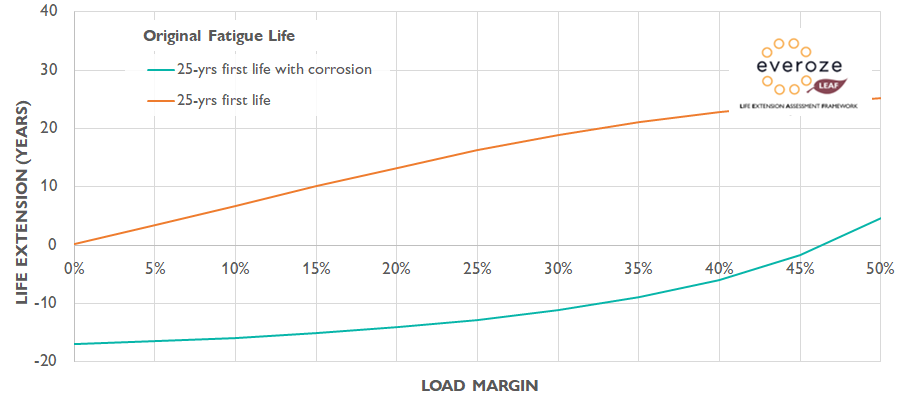

Design assumptions: Simplistically, the biggest impact on life extension will be the loads experienced by the foundation during operation vs. what was assumed for design. Where the operational loads are significantly lower (either through conservative WTG loads or an overestimate of environmental loads), there is a margin which will increase the fatigue life of the structure thereby allowing for a life extension. The figure below presents potential fatigue life extension vs. load margin for a generic case (orange), where reduced operational loads, compared to the design assumption (increasing loads margin on the x-axis) results in scope for life extension (on the y-axis).

More recent projects are benefiting from foundation design optimisation, with measurements complimenting, or even substituting, more conservative modelled loads. This means that additional design margin, which could be relied upon for additional life extension is being eroded through optimised design.

Ground conditions: While ground conditions are usually developed from site-specific measurements, the extent of these measurements can lead to conservatism in the foundation design, increasing steel thickness and embedment depth. On the flip-side, get the soils interpretation wrong and you may be piling-the-heck out of foundations during installation and eating into their fatigue life. In addition to this, where design assumptions on scouring have been underestimated significant pits can develop which affect the stiffness of the structure, again affecting fatigue life.

Operational asset integrity: A fancy way of saying, how well kept is your foundation. Corrosion is perhaps the biggest enemy of integrity, and all foundations will have some level of external corrosion protection. However, in some cases, protection internal to the monopile foundation was deemed unnecessary, as the oxygen in the water trapped internal to the foundation was expected to deplete over time. A reasonable conclusion, until the slippage of transition pieces due to grout failures led to internal J-tubes damaging their seals which in turn allowed the passive exchange of seawater into the monopile, thereby resulting in unplanned corrosion. In addition to this, there is some debate on whether cable entry seals can truly be water-tight. If left unchecked, even for a few years, the effects of corrosion can be significant, as shown in Figure 1, where the effects of free-corrosion can dramatically reduce the life expectancy of a foundation (green) – in some cases it may be a challenge even to reach the originally intended design life, let alone extend further.

—————————————

So, what is the point of this monologue? Well, from an investor’s perspective, what questions should you be asking yourself regarding foundation life extension? The types of question will very much be driven by the vintage of the asset you are interested in, but the following provides examples for projects at various stages of inception/operation:

- What is the history of this project, how was it installed, has it suffered from scour or water ingress – potentially leading to internal corrosion?

- What level of monitoring is in place for operation projects (internal water levels, ph. testing, subsea crack or scouring inspections, etc.)? Is this inspection & monitoring campaign fit for purpose to support engineering integrity assessments for life extension?

- Have the wind turbines/foundations been instrumented to assess operation loads vs. design loads, thereby allowing operator to quantity any load margin and re-estimate fatigue life?

- In addition to (3) above, have adequate foundation installation records been kept to assess piling damage?

- Projects in construction/development have been subjected to improvements in design approach and now carry significantly less margin in material than early projects. If a foundation has been designed for 25-year, can it really be pushed to 30 or more?

So, does offshore wind want to live forever? Well, who wouldn’t? But with a good design, a well-maintained asset and adequate ongoing monitoring, there’s no reason why a project shouldn’t bask in its golden years.

As always, comments welcome to contact@everoze.com